Currently Empty: $0.00

MEASURING HEADS FOR HOT METALS.

With laser point or laser line

With laser point or laser line

TYPICAL APPLICATIONS

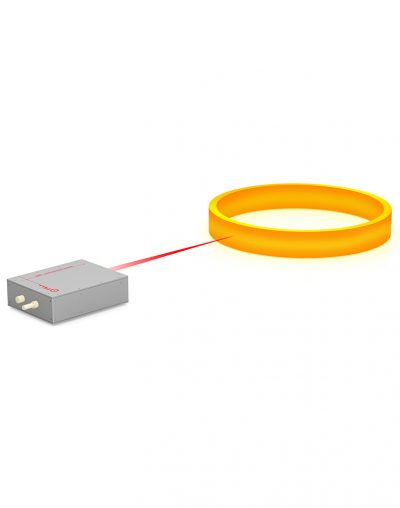

Ring mills

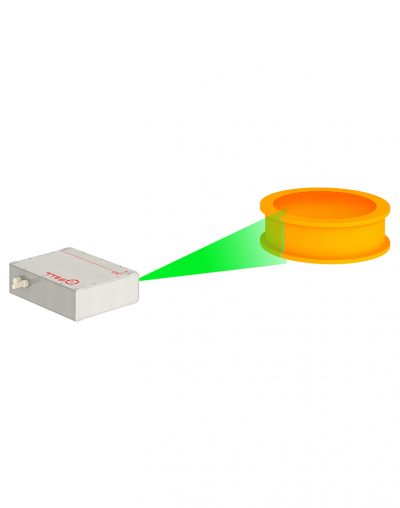

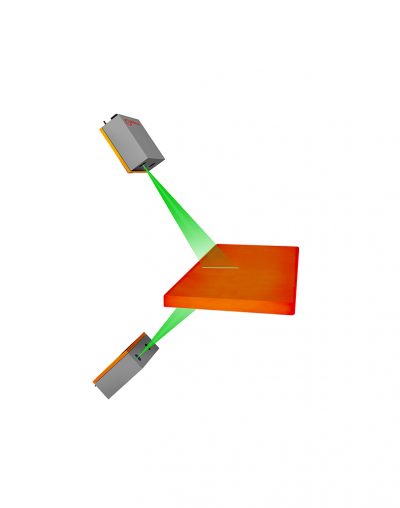

Plate mills

Melting and heating furnaces

Continuous casting lines

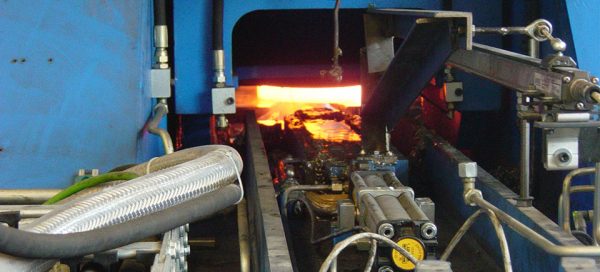

To measure the position of hot materials along laser beam direction. Widely used for diameter measurement of hot rings directly in the lamination process and for level measurement of molten metals.

Wide range of standard models are available with different measuring ranges to measure up to 5 meters distance. Models with customized measuring ranges are available on request.

To measure the profile of hot material along laser line direction. Typically used for thickness measurement of sheets out of the hot plate mill and for profile measurement of hot materials during lamination process.

The measuring heads are designed and manufactured according to the requested application to optimize the performance by modifying the parameters such as: working distance, laser line length, measurement setup, laser power, ….

The measuring heads are based on the laser triangulation working principle by means of robust, fast and reliable measuring sensors, optimized to operate on high temperature metals.

In the LDS series a small laser spot, projected on the material surface and observed by an optical system at a certain angle, provides the measurement in analog and digital form of the material distance from the head.

With the LLS model a narrow laser line is projected on the material section of interest to obtain, with an optical system at a certain angle, the X/Z coordinates of the section. When the material moves along Y direction, it is possible to obtain the continuous 3D exploration of the entire surface.