Currently Empty: $0.00

KLT Profile Gauges

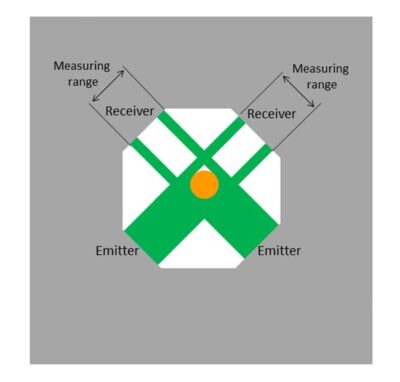

The gauge is designed to measure the diameter of round materials on hot processing line based on the optical telecentric projection principle. The material is illuminated from one side by a homogeneous light source (emitter). From the opposite side, an optoelectronic system (receiver) detects the position of light/dark transition produced by the material edges. Since the optical system is made to provide an optical parallel projection, the measure is stable even in presence of a certain material displacement from nominal pass-line.

Call or Email For Pricing

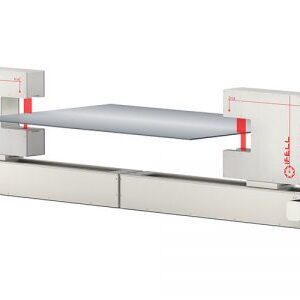

The measuring head is equipped with two emitter-receiver pairs at 90° to measure diameters and ovalization. It is built to provide heavy-duty protection to the optoelectronic components, it is equipped with optical windows air blowing system and it is thermally insulated and cooled with air/water cooling circuits.

To make measurement possible, the user must keep the material edges inside the specified measuring range with suitable external devices.

Measuring result is displayed both on the operator panel with immediate indication of out-of-tolerance condition and stored on Control Report, user available to be exported.

GAUGE DESCRIPTION – TYPICAL SUPPLY

1. Measuring unit, complete with:

- O-Frame in steel construction with double wall insulation system, air and water cooling circuits with control of internal temperature, high-level protection for optoelectronic components and optical windows air blowing system.

- n.2 optical projection telecentric systems at 90° with green backlight and CMOS camera.

- set of interconnection cables (L=10m)

1. Instrument air treatment unit GTA, complete with manual cutoff valve, water separator, filter, microfilter and pressure regulator.

2. Cabinet CPC-5/24, complete with:

o operator panel PPC-5, touchscreen monitor LCD 5.7”.

o installation of application software with the following main functions:

o parameters setting

o display of measured values (2 axis+ovalization)

o alarms + control report

o system CPU

o power-on switch

o user I/O terminal blocks

o 24 Vdc power supply

WORKING MODE

When material is present within the measuring range, the measured values are digitally displayed in green color when in tolerance, in yellow color when out of pre-alarm tolerance (UPL-LPL), in red color when out of tolerance (UTL-LTL). Alarm outputs are activated. They can be connected to external lamps and/or buzzers.

It is possible to issue a measurement report within an interval defined by START-STOP commands. The report includes reference values, measured values, alarms, time, date and statistic (min, max, average, range, sigma). At STOP command, the report is automatically saved into local .csv file and available to be imported from external PC. The report remains stored into the measuring system up to the maximum memory capability.

There are no reviews yet.