Currently Empty: $0.00

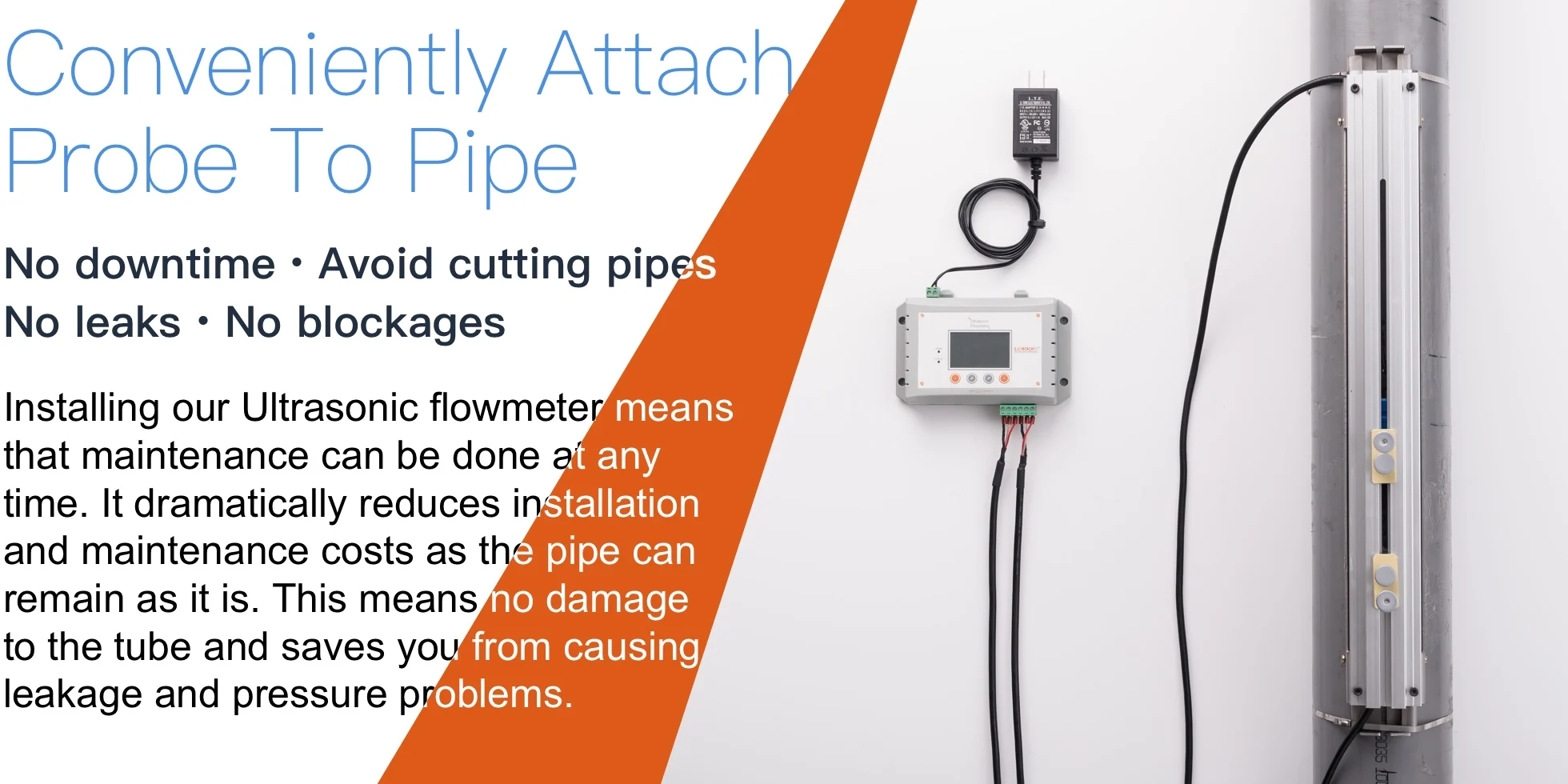

FU-TX 310 clamp-on ultrasonic flowmeter

Apply for:-

Energy-saving monitoring│Water-saving management│Industrial use│Tap water, cool water, hot water, raw water, sea water, beverages, oil and other liquid.│ Power plants (nuclear power, fire, water)

Call or Email For Pricing

Product of Taiwan, Non invasive design, no down time for installation, no pipe cutting, maintenance at any time, significantly reduce installation and maintenance costs. Tube installation-zero tube damage, no blockage, no leakage and pressure problems.

Features:-

Other Important Features

- Universal Power Adapter.

- Bidirectional flow measurement.

- Patented trigger technology increases ability of anti-interference.

- Optional water-resistant probes.

- Patented guide rails for probes provide quick install, precise positioning and long-term stable measurement.

- Made in Taiwan.

Specification:-

| Installation method | Tube clamps | Power consumption | 2W |

| Measurement principle | Time differential | Transient flow | Instantaneous flow, flow velocity, time differential display |

| Flow rate range | ±0.1~20m/s | Cumulative flow | Positive and negative cumulative, net flow display |

| Measurement accuracy | ±2 % | Units | Metric or Imperial units |

| Response time | 1 second | Display | 128 x 64 LCD backlight display |

| Resolution | 0.0001 m/s | Operation button | 4 touch button |

| Wired communication | Analog output 4-20mA

Modbus RS485 Two-line |

Security | Keyboard lock, power-loss data protection |

| Probe-to-host distance | TM-1: 10 meters (Up to 20 meters)

TS-2 10 meters |

Shell | ABS plastic, 145 x 90 x 45 mm |

| Temperature measurement | Two sets of external PT1000 | Power |

9~30VDC 100-240 50 / 60Hz AC transformer |

| Temperature range | -100~300°C with 0.1°C resolution | Applicable pipe material | Cast iron, carbon steel, stainless steel, PVC pipe and other |

| Device working temperature |

-10~60°C (14~140°F) | Applicable pipe diameter (mm) | TM-1 DN50-250 (2″~10″)

TS-2 DN20-50 (¾” to 2″) |

| Applicable fluid | Clean water, oil or chemical with minor impurities | Probe waterproof rating |

General probe IP61 Glue probe IP65 Waterproof resistance probe IP68 |

| Wall temperature |

Standard probe:0~80°C High temperature probe:0~150°C |

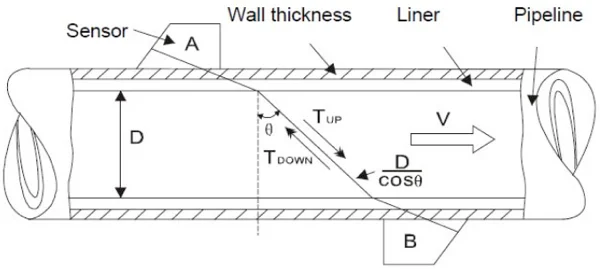

Principle

- Ultrasonic measurement of forward and reverse flow time difference: When the ultrasonic wave is transmitted between probe A and probe B, the direction of forward flow and reverse flow will produce a time difference proportional to the flow rate

- Accuracy of up to 2%

- LORRIC special anti-noise technology can reduce the interference of bubbles and solid parts.

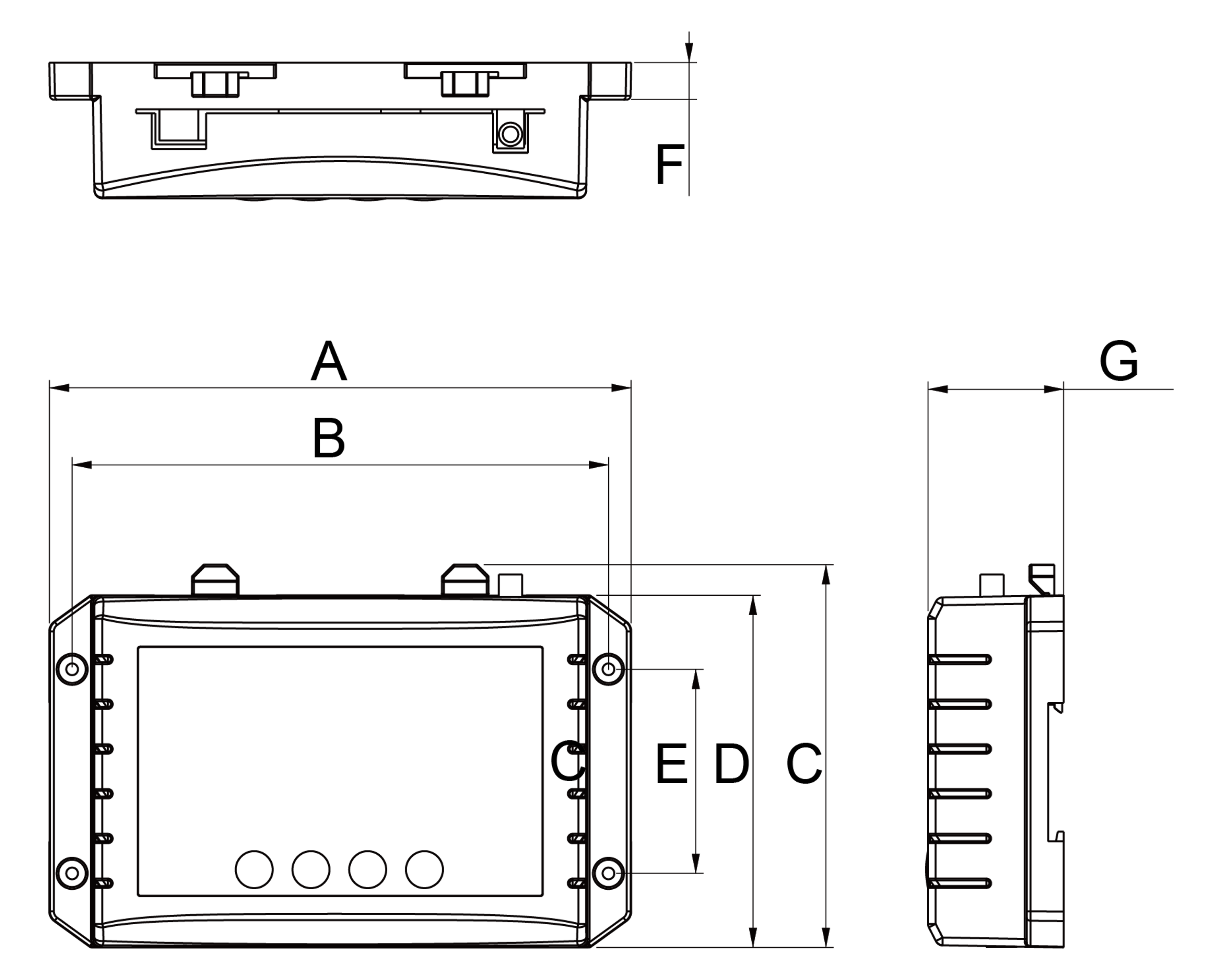

Size:-

|

|||||||||||

| A | B | C | D | E | F | G | |||||

| 149.45mm | 137.79mm | 98.32mm | 90.45mm | 52.42mm | 9.5mm | 34.85mm | |||||

|

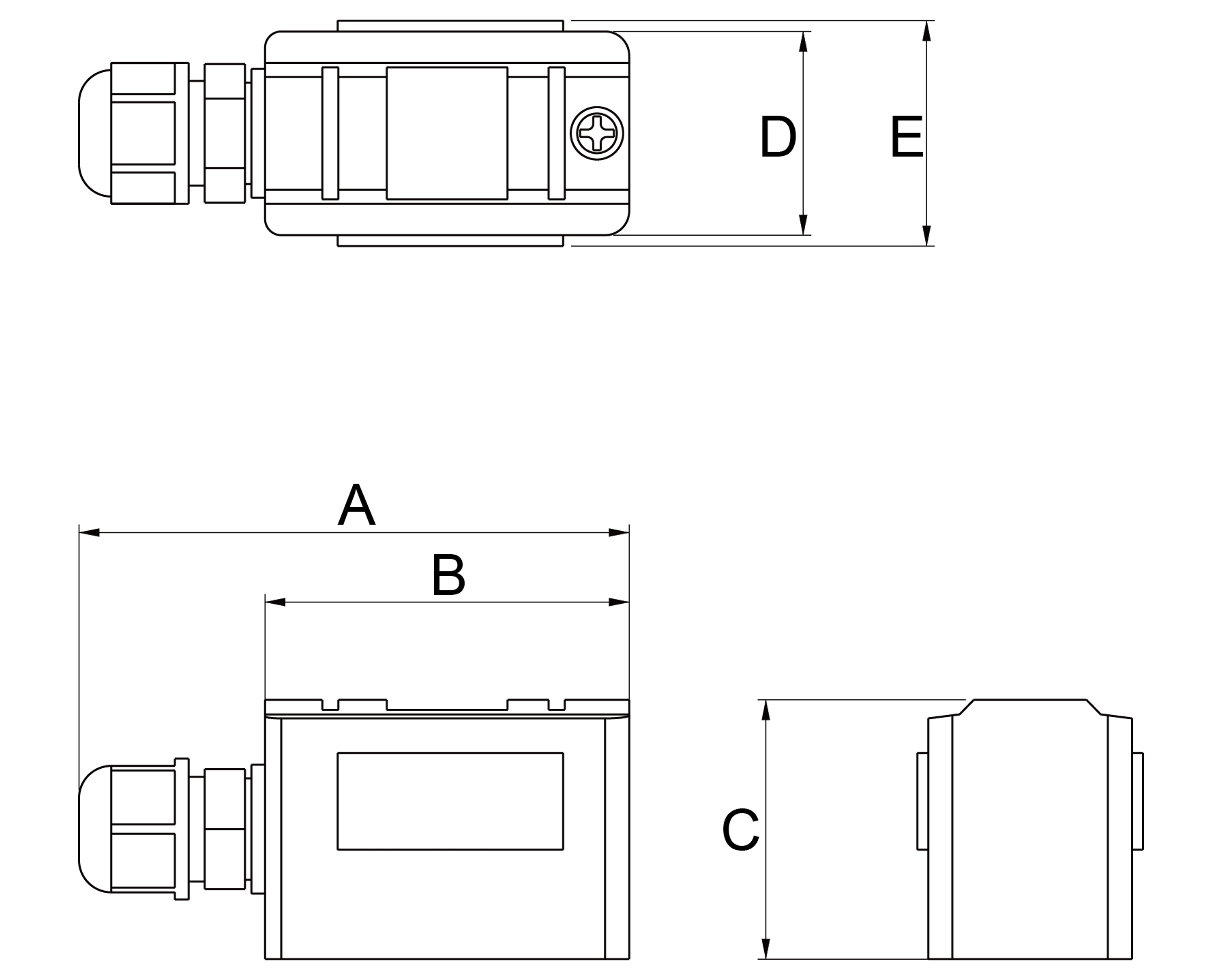

||||

| A | B | C | D | E |

| 68.3mm | 45.2mm | 32.2mm | 25.3mm | 42.6mm |

Comparison with flowmeters with other various principles

| Variable area flowmeter | Paddle wheel flowmeters | LORRIC’s Paddle wheel flowmeter |

Electromagnetic flowmeter | Ultrasonic

flowmeters |

|

| Pipeline loss | Low | Low | Low | No | No |

| Non-invasive install | No | No | No | No | Yes |

| Precision | Middle | Middle | Middle | High | High |

| Bidirectional flow detectable | No | No | Yes | Yes | Yes |

| Blockages | Possible | Possible | Possible | Not possible | Not possible |

| Applicable fluid | Air / Liquid | Liquid | Liquid | Conductive liquid | Liquid |

| Cost | Lowest-costs in small diameter pipe, cost increases with pipe diameter | Low-costs, cost increases with pipe diameter |

Low-costs, cost increases with pipe diameter |

High-costs, cost increases with pipe diameter | Middle-costs Cost does not increase with pipe diameter |

There are no reviews yet.