Currently Empty: $0.00

IFELL Thickness Gauge: Usefulness & Where to Get It

A thickness gauge, like IFELL thickness gauge is used to measure the paint thickness, revealing or reprinting the spots in any material required, and that’s too correctly.

Thickness gauges are nothing but measuring instruments highly useful for wide range of applications. Actually, the thickness gauge is used to determine the thickness or the gauge of a certain material. Normally, there are many different types of thickness gauges available in the market.

While choose IFELL thickness gauge, you need to understand each that function in a slightly different ways depending on the intended application for the purpose of gauge. Here, in this article, we will discuss the use of thickness gauges, and where to buy the best one.

Types and Usage of Thickness Gauges

In actuality, term “thickness gauges” have several meaning, and might refer to one of the following types. Let’s discuss them in a brief.

• Coating thickness gauges

• Material thickness gauges

• Sheet and wire metal thickness gauges

The coating thickness gauges measure material thickness efficiently by mechanical means and a calibrated instrument which is very closed around the sample till contact is made with each side of the material, but a process similar to that of a micrometer. For the sake of this article, these thickness gauges would be referred to as material gauges.

The next thickness gauge described here is especially designed to measure the thickness of coatings of various types applied to a surface and these are also known as coating thickness gauges. The third one is a thickness gauge, which is simpler and highly powerful mechanical device which is used to measure wire as well as sheet metal thickness correctly.

Put it simply, a thickness gauge of either type, like IFELL thickness gauge is an essentially a powerful tool in the time you anodize, or apply zinc coating to metallic surfaces. If you want to measure the body paint thickness and uniformity or anything, like any material or for example, on a pre-owned car, then a thickness gauge is important. It helps you reveal, repaint or identify the hidden damage and expose the undisclosed accidents.

To Sum It Up

There are many sellers and manufacturers in the market offers IFELL thickness gauge, but keeping them aside why choose Gordy’s thickness gauge? The answer is pretty simple! The thickness gauge offered by Gordy’s Sensors is based on the optical triangulation principle of a laser line, which is observed by high resolution isochromatic camera.

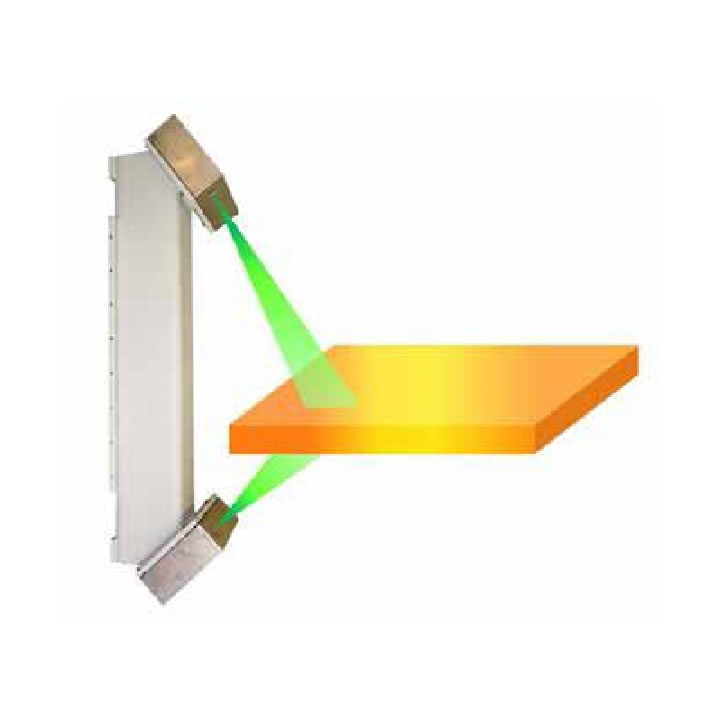

You must know that it is nothing but an optical measurement method sans contact, and that’s too without hazard radiations. If you are using this type, then you must know that 2 measuring heads are normally mounted, 1 on the top and other 1 on the bottom of a heavy-duty I-Frame, and that’s too at a certain angle of inclination in the way of material surfaces, so that it works from outside of the material running area.

It also sees if it can work in a safer position rather than just over and below setup and requests by the typical measurement configuration with the help of C-Frame. Actually, a thin laser line is typically projected on each of the 2 essential material surfaces. It is also observed by the necessary camera by way of a proper optical system.

Let us close by saying GS-2000 series thickness gauge offered by Gordy’s Sensors is one of the best in the market. If you choose Gordy’s Sensors, rest assured you have chosen the best!