Currently Empty: $0.00

Recognize 3 core reasons to use the Laser Thickness Gauge System

Most production processes need constant tracking of the product thickness for rendering feedback to manage the product attributes. In this context, the thickness of the product might get altered due to the manufacturing line wear and tear, or the alterations in the uniformity rate of the industrial raw materials. With the advancement in optoelectronics, the laser displacement sensors are also operating with enhanced accuracy, resolution, and magnitude of applications.

Operating with a high-resolution isochromatic camera and on the concept of optical triangulation, the Laser Thickness Gauge System from Gordy’s Sensors is an innovative measuring method that functions contactless while negating radiation threats. This unique system is designed to operate in the production lines of assessing materials with high thickness variations that are either static or running, and cold or hot.

How Does The Laser Thickness Measuring Sensors Function?

Functioning with the top-of-the-line optical measurement process and on the principle of optical triangulation, the laser thickness assessing sensor devices determines the precise thickness via the HD isochromatic camera. This one-of-a-kind device operates contactless and eliminates any possibilities of radiation hazards.

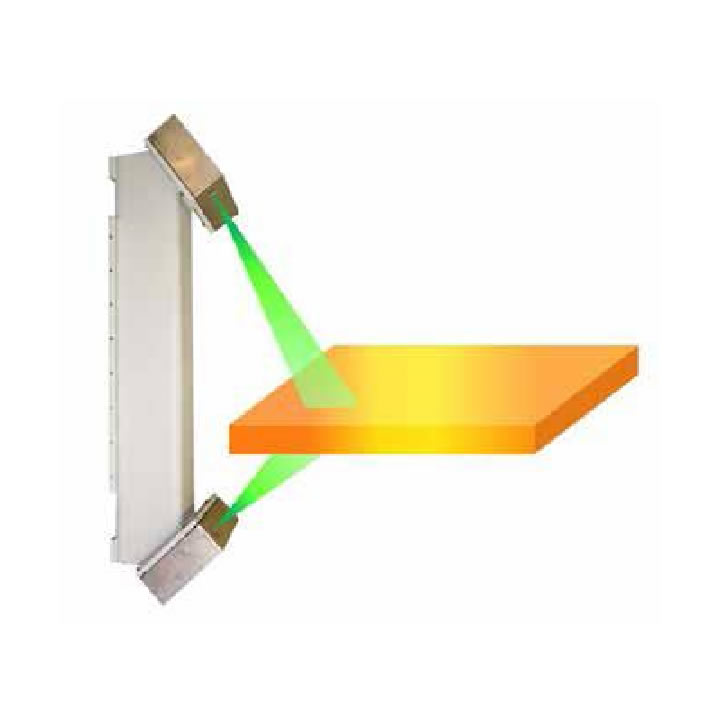

The sensor comes with two discrete measuring heads that are mounted on the top and bottom of a highly resilient I-Frame at a precise oblique angle with the material surfaces. In the process, such heads quantify the position of the specific measuring surface along with the laser line. This unique evaluating system is designed to operate in the production lines for gauging materials having high thickness disparity that is either hot or cold and fixed or running.

The thin laser line is directed on each of the two material surfaces, which is detected by the HD camera through the optical triangulation technique. After measuring the position of the head along the laser line on the suitable surfaces, the material density is computed from the fusion of the quantified points, considering the gradient and distance of the two heads. It is to be noted that the system accuracy is equivalent to the measuring range and neutral from the material composition and density.

What Are The Pivotal Facets To Use The Laser Line Technique To Measure Surface Density?

- Laser Line Delivers Optimally Precise Results

The highly functional laser line technology operating on the optical triangulation principle offers multiple mileages. In this context, the precise measurement done by the sensor applying this innovative technique is not affected by the breaches in the signal triggered by the particles or steam. Besides, the laser line can easily detect the surface sheet edges, along with the tilting, whereupon the thickness accuracy is corresponding to the flat, as well as the tilted sheets. Again, the surface width can also be measured by utilizing two C-frame systems.

- Economical Measurement Solution

When applying such laser-based thickness measurement systems, typically the acquisition and operating expenses are considerably lower than other assessing techniques of X-ray. In this context, it is to be noted that the laser diode comes with enhanced durability, and lasts for several years. In this case, the lasers can also be deactivated, when not in operation for extending their shelf life.

- Streamlined Application with Optimum Time Savings

Unlike the radiometric measurement systems that need higher maintenance and adjustment, the laser-based thickness assessment solutions are relatively simpler to use. Such laser-centric optical measurement techniques execute the alignment spontaneously and swiftly, assuring that it can be operated between two surfaces. Since such laser thickness measurements can be executed autonomously of the surface or material, the defacements to the object can be minimized.

Besides, such laser thickness measurement sensors are quite easy to maintain. However, in scenarios of heavy adulteration, the system will automatically issue alerts and messages. Moreover, as these lasers are utilized in the measurement process come with a class 3R rating, they can be comfortably turned off for smoothly and quickly carrying out the maintenance functions.

Final Verdict

With 14 years of specialized expertise in supplying premium quality monitoring, sensing, and measuring products, Gordy’s Sensors is undeniably the one-stop solution for industrial users. Such a unique Laser Thickness Gauge System functioning on optical triangulation technique with an HD isochromatic camera can prove to be perfect in devising accurate measurements for assessing the product thickness. It also becomes worthy, as this unique system can effortlessly function in either running or static, and also the cold or hot mediums.